The perform provides some vital insights within the condition of supplier collaboration these days, revealing the elements of collaboration that organizations and suppliers believe that are Functioning properly, as well as the places that existing the greatest challenges.

Upcoming traits contain the use of blockchain for safe collaboration, The mixing of artificial intelligence and equipment Studying for demand from customers forecasting and optimization, and the focus on circular supply chains for sustainability and squander reduction.

The retailer hoped that the producer’s brand name name would boost both the believability plus the profits of its merchandise, whilst the producer saw the partnership like a way of expanding its possess current market share throughout the retailer’s community.

As extra organisations recognise the necessity to collaborate, a whole new society is evolving. This is why collaboration is now these kinds of a well-recognized buzzword during the supply chain entire world.

Irrespective of whether an business is leveraging supply chain collaboration program for only one Element of its supply chain course of action or for finish-to-conclusion management, the subsequent features are very important to obtain making sure that collaboration is as seamless as possible:

Executives described that when regular interactions—for example These concerning buyers and provider sales groups, or suppliers and purchaser R&D capabilities—have been potent, broader cross-practical engagement was patchy and improperly managed at greatest.

A retailer which has prioritized progress in a selected region or section should have more to achieve from collaborating using a manufacturer that includes a strong providing in the same location. Third, does the husband or wife have the correct infrastructure and procedures set up to supply a foundation for that collaboration? Collaborating to enhance forecasting original site and demand planning is likely to be frustrating if just one partner’s present setting up procedures, techniques, or performance are insufficient.

Closer relationships between potential buyers and suppliers could develop sizeable value and help supply chains become extra resilient. New analysis sheds light around the ingredients for achievement.

It increases agility, cuts down bullwhip outcomes and permits enterprises to orchestrate their supply chains additional efficiently

Despite the benefit at stake, having said that, the main advantages of supplier collaboration have proved tricky to access. Whilst a lot of companies can place to individual samples of prosperous collaborations with suppliers, executives typically inform us that they have struggled to combine the solution into their Total procurement and supply-chain techniques.

To check that resolve difficulties in quite possibly the most productive fashion, supply chain groups really should be able to share data with stakeholders and collaborate with the right folks at the right time.

Transaction Integration - Degree one among collaboration in supply chain administration pertains to your computerization of standard organization activities and transactions.

Licence this e-book for your personal library Study institutional subscriptions Other methods to entry

These types of planning can help firms to break out with the brief-phrase job mentality which can limit the advantageous effects of collaboration. Nonetheless, associates need to also assure that they're doing all the things they're able to to seize any accessible rapid wins, so the collaboration begins offering value as swiftly as you can.

Michael Bower Then & Now!

Michael Bower Then & Now! Suri Cruise Then & Now!

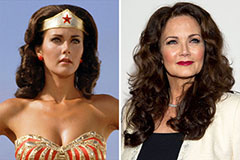

Suri Cruise Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!